CAPABILITIES

Summary Equipment List

1 - Mitsubishi 4kw Laser w/ MSCIII Auto-Flex MS HP Automation

1 - Trumpf Punch

1 - Accurpress Press-Brake: 175 ton, 12' bed

1 - Accurpress Press-Brake: 60 ton, 6' bed

1 - Pacific Press-Brake: 165 ton, 10' bed

4 - HAAS VF-3 Vertical Milling Machines

2 - HAAS SL-20 and SL-30 w/ Bar-Feed Automation

2 - Marvel Auto Feed Saw

1 - Col-Met Powder Booth

1 - Col-Met Oven

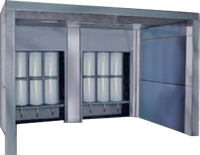

1 - DeVilbis Cross-Flow Paint Booth

1 - Sandblast Facility w/ Empire Dust-Collector

Please note: in addition to the equipment listed, Versa-Fab has a manual machine shop with three mills and two lathes, 20 weld-centers with equipment and positioners, material-handling equipment, various quality equipment, and two delivery trucks.

1 - Mitsubishi 4kw Laser w/ MSCIII Auto-Flex MS HP Automation

1 - Trumpf Punch

1 - Accurpress Press-Brake: 175 ton, 12' bed

1 - Accurpress Press-Brake: 60 ton, 6' bed

1 - Pacific Press-Brake: 165 ton, 10' bed

4 - HAAS VF-3 Vertical Milling Machines

2 - HAAS SL-20 and SL-30 w/ Bar-Feed Automation

2 - Marvel Auto Feed Saw

1 - Col-Met Powder Booth

1 - Col-Met Oven

1 - DeVilbis Cross-Flow Paint Booth

1 - Sandblast Facility w/ Empire Dust-Collector

Please note: in addition to the equipment listed, Versa-Fab has a manual machine shop with three mills and two lathes, 20 weld-centers with equipment and positioners, material-handling equipment, various quality equipment, and two delivery trucks.

Quality Machining and Fabrication